H&P Reduces BHA Count From 3 to 1 and Saves an Estimated $165,000

Challenge

A major operator drilling in the Woodford formation of central Oklahoma wanted to reduce stick slip, which is a common issue while drilling wells in the relatively young Merge play. This reoccurring issue often caused costly bit and bottom hole assembly (BHA) damage, leading to additional time spent on the well due to extra trips and BHA changes.

Solution

H&P identified the key challenges and recommended FlexTorque® software as a resolution.

FlexTorque technology reduces vibration from stick slip that can lead to BHA damage by maintaining constant bit speed based on the model created by the unique BHA configurations.

Outcome

After installing FlexTorque software on one of wells and comparing its KPIs to a well that did not install H&P technology, the operator recognized the true impact FlexTorque technology had on achieving their desired outcome.

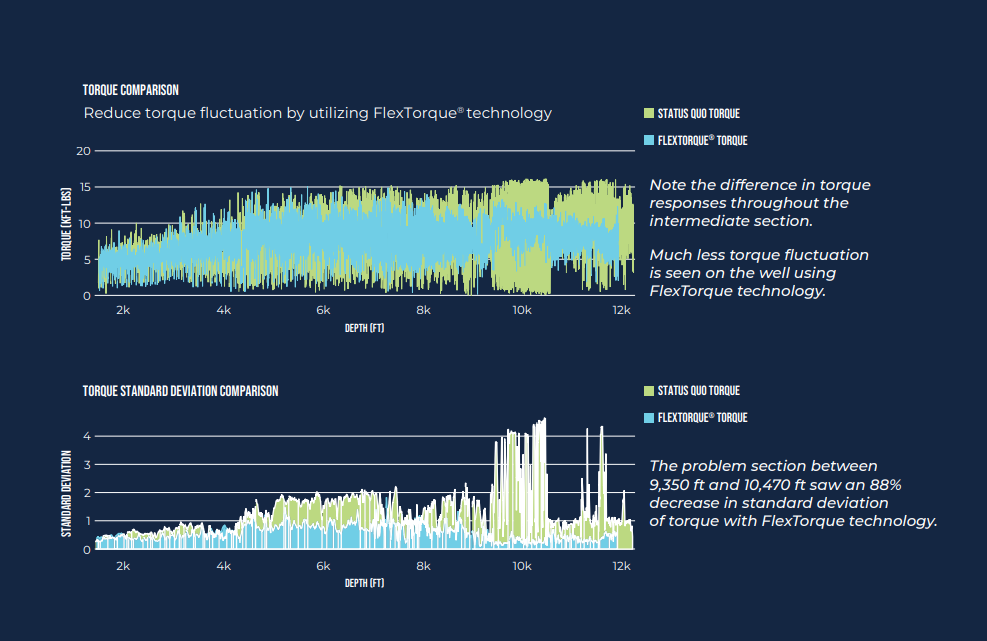

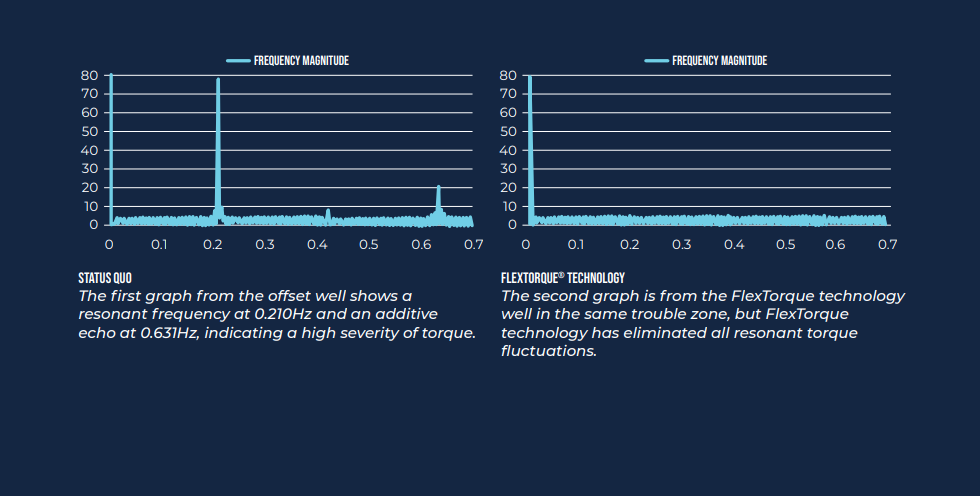

Torque Standard Deviation

64% reduction in the average torque standard deviation, indicating a smaller severity of torque swings

Intermediate Section BHA Count

66% reduction in total intermediate BHA count – reduced from a total of three to one.

Total Days on Intermediate Section

20% time savings of total days spent drilling the intermediate section – a reduction from 8.3 days to 6.6 days.

Additional Savings

$165,000 estimated cost reduction from nonproductive time and BHA savings.

Past performance is not a guarantee of future results. Any statements regarding past performance are not guarantees of future performance and actual results may differ materially. © 06/2021 HPCS005